Best Explosion Proof Flood Lights for Oil & Gas Facilities

In oil and gas facilities where explosive gases, flammable vapors, and combustible dust create life-threatening risks every single day, one lighting failure can trigger catastrophic consequences. Workers operating in refineries, drilling platforms, and petrochemical plants face constant danger from potential ignition sources, making the selection of Explosion Proof Flood Lights not just a regulatory requirement but a critical safety imperative that directly impacts lives, operational continuity, and corporate liability. This comprehensive guide reveals the essential features, technical specifications, and proven solutions that distinguish superior Explosion Proof Flood Lights from inadequate alternatives, empowering facility managers and safety engineers to make informed decisions that protect personnel while optimizing operational efficiency in these hazardous environments.

Why Explosion Proof Flood Lights Are Essential for Oil & Gas Safety?

Understanding Hazardous Location Classifications in Petroleum Facilities

Oil and gas facilities operate under stringent hazardous location classifications defined by organizations like the National Electrical Code and ATEX directives. Class I Division 1 areas, where flammable gases and vapors are continuously or intermittently present during normal operations, demand the highest level of explosion protection. Class I Division 2 zones, where ignitable concentrations exist only under abnormal conditions, still require certified Explosion Proof Flood Lights to prevent catastrophic incidents. Understanding these classifications is fundamental because installing non-compliant lighting equipment in refineries, offshore platforms, or natural gas processing plants can result in devastating explosions, regulatory violations, massive fines, and irreparable damage to both human lives and corporate reputation. Explosion Proof Flood Lights designed for these environments incorporate specialized enclosures engineered to contain internal explosions and prevent flame propagation to the surrounding atmosphere, effectively eliminating ignition sources in areas containing propane, butane, gasoline, hexane, naphtha, benzene, and other volatile petroleum products.

Critical Safety Standards and Certification Requirements

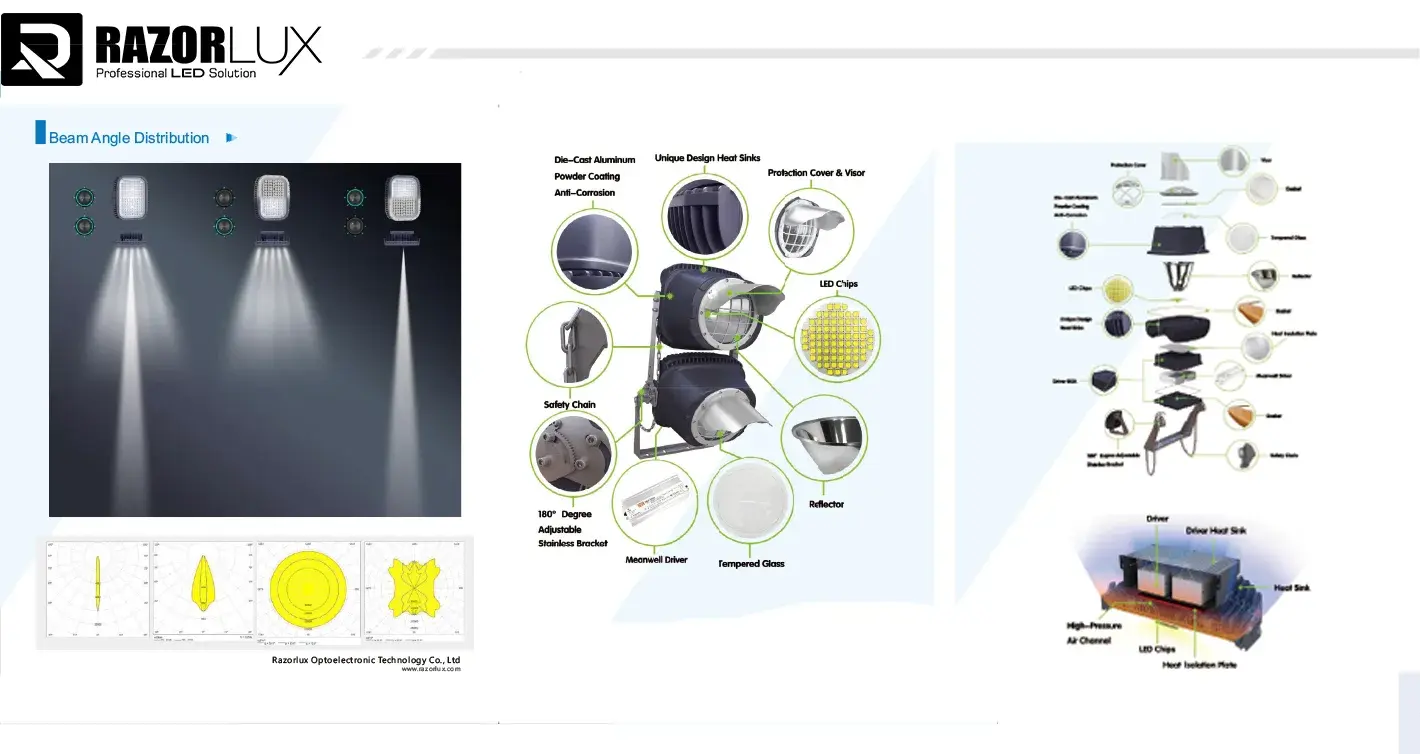

Compliance with internationally recognized safety standards represents the non-negotiable foundation for Explosion Proof Flood Lights deployed in oil and gas facilities. ATEX certification for European markets, UL and CUL approvals for North American installations, and IECEx recognition for global projects ensure that lighting fixtures have undergone rigorous testing to withstand internal explosions without rupturing their enclosures. The IP68 rating guarantees complete protection against dust ingress and sustained immersion in water, essential for offshore platforms and coastal refineries exposed to harsh marine environments. Additional certifications including DLC for energy efficiency, PSE for Japanese markets, SAA and C-TICK for Australian compliance, CQC for Chinese installations, CE marking for European conformity, and RoHS for environmental sustainability demonstrate comprehensive quality assurance. Xi'an Razorlux Optoelectronic Technology Co., Ltd. manufactures Explosion Proof Flood Lights that meet all these stringent standards, providing oil and gas operators with certified solutions backed by over 200 patents covering LED Packaging, power control systems, and structural engineering innovations specifically designed for hazardous industrial applications.

Real-World Consequences of Using Non-Compliant Lighting Solutions

The petroleum industry's history contains sobering examples of catastrophic incidents triggered by inadequate lighting equipment in hazardous locations. Non-explosion-proof fixtures lacking proper flame path engineering have ignited flammable atmospheres, causing explosions that killed workers, destroyed facilities worth hundreds of millions, and contaminated surrounding communities with toxic releases. Insurance companies deny coverage, regulatory agencies impose operational shutdowns, and criminal prosecutions target executives when investigations reveal non-compliant equipment contributed to disasters. Beyond immediate casualties, companies face bankruptcy-level financial losses from litigation, environmental remediation, regulatory penalties, reputation damage, and lost production capacity. Conversely, investing in certified Explosion Proof Flood Lights from reputable manufacturers protects organizations legally, operationally, and morally. These fixtures undergo hydrostatic testing at four times maximum internal explosion pressure to verify their enclosures won't rupture, incorporate precisely engineered flame paths between housings and door frames to cool burning gases before escaping, and maintain surface temperatures below ignition thresholds of surrounding explosive atmospheres, creating multiple layers of protection that transform lighting from potential ignition source to reliable safety asset.

Technical Features That Define Superior Explosion Proof Flood Lights

Advanced LED Technology and Optical Performance

| Technical Specification | Standard Performance | Razorlux Superior Performance |

|---|---|---|

| Power Options | Single wattage | 30W, 80W, 100W, 180W flexible configurations |

| LED Chip Quality | Generic components | High-efficacy 700mA low-decay Bridgelux chips |

| Luminous Efficacy | 90-110 lm/W | 130-140 lm/W professional grade |

| Light Transmission | 80-85% standard glass | 95% super-clear tempered glass |

| Color Temperature | Limited options | Customizable 3000K-6500K range |

| Lifespan | 30,000-40,000 hours | 50,000+ hours rated operation |

Modern Explosion Proof Flood Lights incorporate cutting-edge LED technology that revolutionizes illumination in oil and gas facilities compared to obsolete HID and metal halide systems. High-efficacy 700mA LED chips deliver exceptional luminous output while generating minimal heat, crucial for maintaining surface temperatures below explosive atmosphere ignition points. The original Bridgelux LED sources provide industry-leading luminous efficacy and extended lifespans exceeding 50,000 hours, dramatically reducing maintenance costs in hazardous locations where accessing fixtures requires hot work permits, gas monitoring, and extensive safety protocols. Scientific optical reflector designs eliminate glare while focusing light precisely where needed, creating uniform, comfortable illumination that enhances worker safety and productivity. Anti-glare properties prevent the vision impairment that compromises situational awareness during critical operations. Shock and vibration-resistant tempered glass lenses achieve 95% light transmission rates while withstanding the mechanical stresses common in industrial environments. These advanced optical systems transform raw LED output into professionally engineered lighting solutions optimized specifically for the demanding requirements of petroleum facilities.

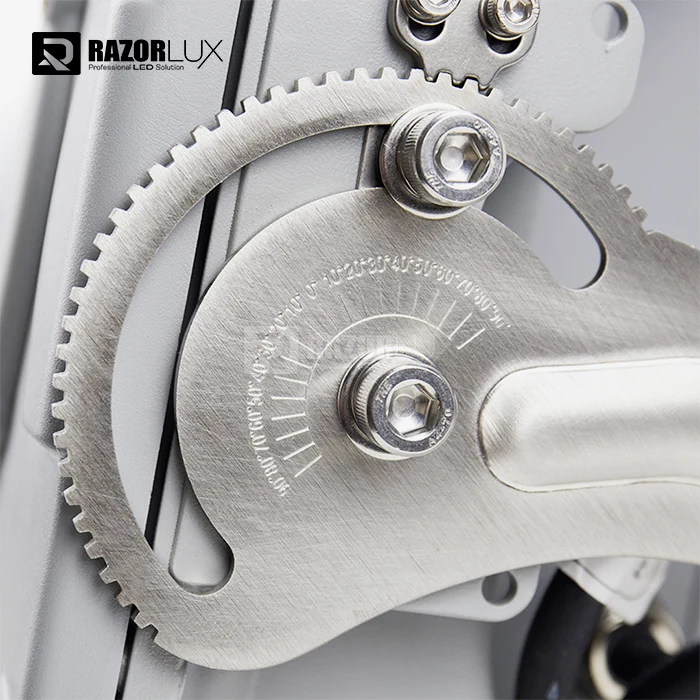

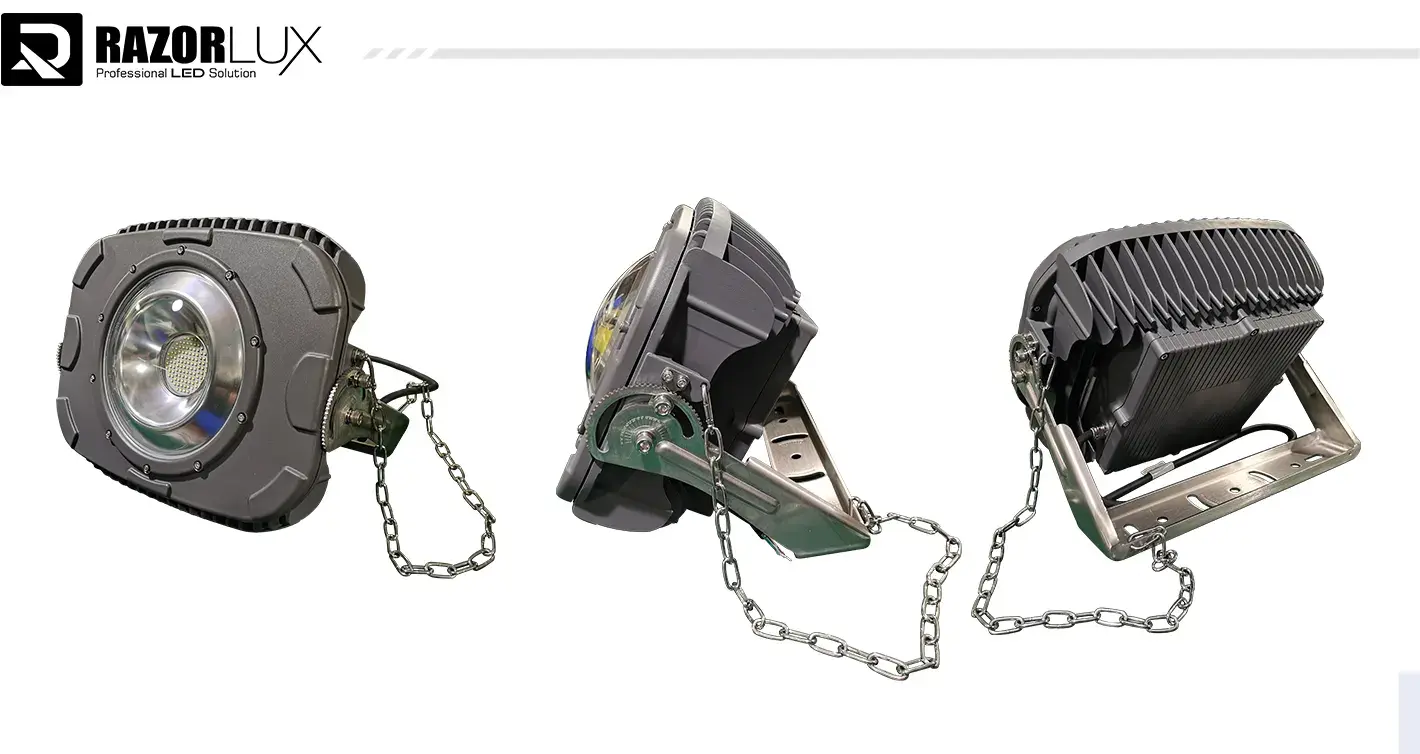

Thermal Management and Durability Engineering

Effective thermal management separates professional-grade Explosion Proof Flood Lights from consumer-level alternatives unsuitable for industrial deployment. High heat transmission die-cast ADC12 aluminum housings combine superior structural strength with exceptional thermal conductivity, rapidly dissipating LED-generated heat to prevent junction temperature degradation that accelerates lumen depreciation and premature failure. The patent-design housing architecture maximizes surface area for convective cooling while maintaining explosion-proof integrity. Premium 2.0mm aluminum PCB substrates with 2.5 thermal index ratings maintain LED chips at optimal operating temperatures even in extreme ambient conditions ranging from -30°C Arctic installations to +50°C desert refineries. This sophisticated thermal engineering extends equipment lifespan, maintains consistent light output throughout the fixture's operational life, and prevents the performance degradation that forces premature replacements. Powder-coated surface treatments provide exceptional resistance against salt spray corrosion in offshore platforms, chemical exposure in processing facilities, and dust accumulation in storage tank farms. These treatments create hard, durable finishes that maintain aesthetic appearance while protecting underlying aluminum from degradation that compromises structural integrity. The comprehensive thermal and durability engineering ensures Explosion Proof Flood Lights from Xi'an Razorlux deliver reliable performance throughout their rated lifespan regardless of environmental challenges.

Driver Technology and Electrical Performance Reliability

Premium Explosion Proof Flood Lights incorporate MEANWELL HLG series drivers representing the highest echelon of power supply engineering available in the lighting industry. These top-tier drivers provide stable, regulated current to LED arrays regardless of input voltage fluctuations, ensuring consistent luminous output and protecting sensitive LED components from electrical transients that cause premature failures. Wide input voltage ranges from 100-277V accommodate various electrical systems found in global oil and gas facilities, eliminating the need for expensive voltage-specific inventory. Advanced dimming capabilities including 0-10V and DALI protocols enable sophisticated lighting control systems that optimize energy consumption based on operational requirements, daylight harvesting, and occupancy patterns. The emergency power functionality developed by Razorlux allows Explosion Proof Flood Lights to continue operating for two hours during power failures, maintaining critical illumination for safe evacuation and emergency response procedures. Surge protection up to 10kV guards against lightning strikes and electrical faults common in outdoor industrial installations. The sophisticated driver technology transforms basic illumination into intelligent lighting systems that enhance safety, reduce operational costs, and provide the reliability demanded by mission-critical petroleum operations where lighting failures during emergencies could prove catastrophic.

Comprehensive Selection Guide for Oil & Gas Applications

Matching Wattage and Beam Patterns to Specific Applications

| Application Area | Recommended Wattage | Optimal Beam Angle | Mounting Height | Coverage Area |

|---|---|---|---|---|

| Drilling Rig Platforms | 100W-180W | 60°-90° flood | 8-12 meters | 400-600 m² |

| Refinery Process Units | 80W-100W | 90°-120° wide | 6-10 meters | 300-450 m² |

| Tank Farm Perimeters | 180W high output | 30°-60° narrow | 12-15 meters | 600-800 m² |

| Loading Dock Areas | 80W-100W | 120° extra wide | 5-8 meters | 250-400 m² |

| Pipeline Pump Stations | 30W-80W | 90° standard | 4-6 meters | 150-300 m² |

| Offshore Platform Decks | 100W-180W marine | 60°-90° flood | 10-14 meters | 500-700 m² |

Selecting appropriate Explosion Proof Flood Lights requires careful analysis of specific application requirements within oil and gas facilities. High-output 180W fixtures excel in illuminating elevated drilling platforms, offshore helidecks, and expansive tank farm perimeters where fixtures mount at considerable heights and must project powerful, focused beams across large areas. Medium-power 80W to 100W configurations provide optimal solutions for refinery process units, chemical storage facilities, and loading terminals where mounting heights range from six to ten meters and applications demand reliable, even illumination without excessive energy consumption. Compact 30W units suit pipeline monitoring stations, equipment shelters, and localized task lighting where space constraints or lower ceiling heights necessitate smaller fixture profiles. Beam angle selection dramatically impacts lighting effectiveness—narrow 30° to 60° spot patterns concentrate illumination for long-throw applications, standard 90° flood beams provide balanced coverage for general area lighting, and wide 120° distributions create uniform illumination in confined spaces with lower mounting heights. Professional lighting designers from Xi'an Razorlux conduct comprehensive photometric analyses considering mounting positions, required illuminance levels per industry standards, uniformity ratios, and glare limitations to specify precisely the right combination of wattage, beam distribution, and fixture quantity that optimizes both safety and cost-effectiveness for each unique petroleum facility application.

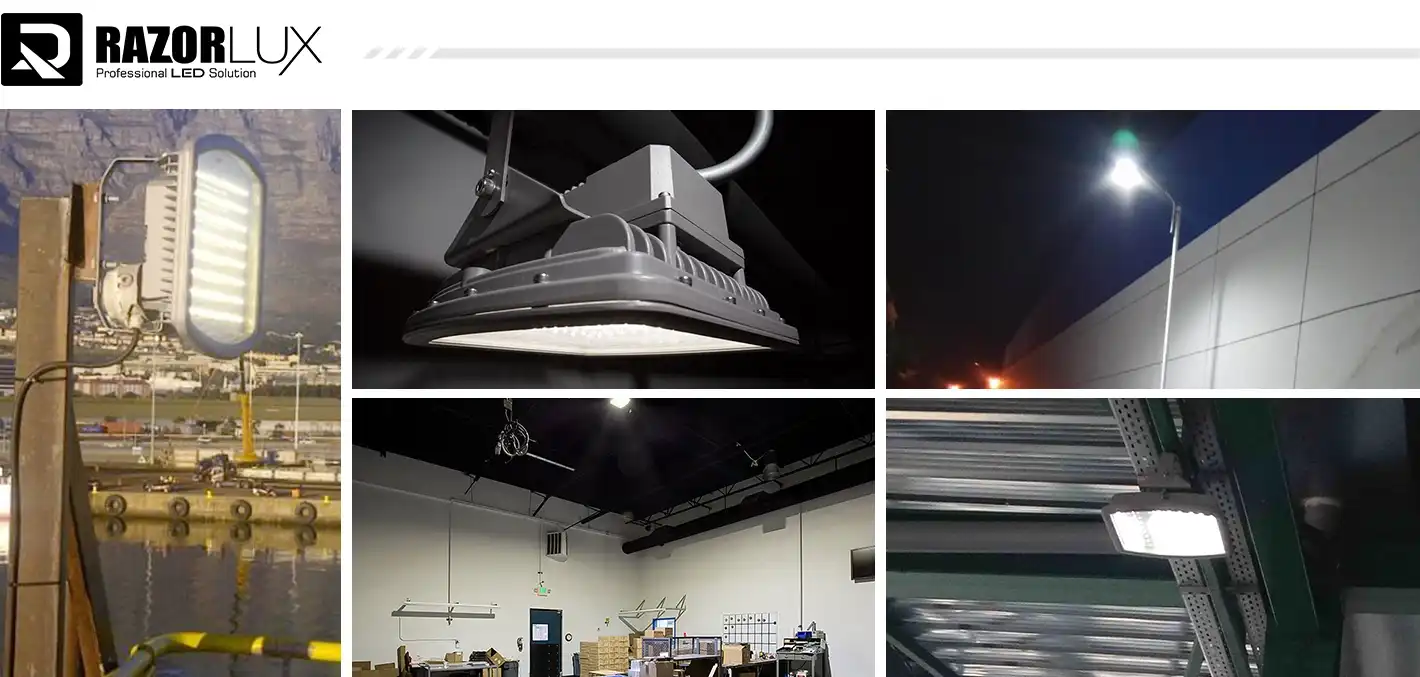

Environmental and Mounting Considerations for Harsh Conditions

Oil and gas facilities present extraordinarily challenging environmental conditions that demand specialized Explosion Proof Flood Lights engineered specifically for harsh industrial applications. Offshore platforms and coastal refineries expose lighting equipment to relentless salt spray, high humidity, and temperature extremes that rapidly corrode standard fixtures. Desert installations subject equipment to intense solar radiation, extreme temperature variations exceeding 80°C between day and night, and abrasive sand infiltration. Arctic facilities operate in temperatures plummeting below -40°C where inferior components become brittle and fail catastrophically. The marine-grade anti-corrosion coatings and IP68-rated enclosures protecting Razorlux Explosion Proof Flood Lights withstand these punishing conditions, maintaining performance integrity throughout their operational lifespans. Versatile mounting options including yoke brackets for adjustable aiming, pendant configurations for overhead suspension, wall-mount solutions for vertical surfaces, and pole-top adaptors for elevated installations accommodate diverse facility layouts and architectural requirements. Vibration-resistant designs prevent mechanical failures in locations subject to ongoing equipment operation, seismic activity, or structural oscillation. Fixtures must also resist impact damage from maintenance activities, accidental contact with mobile equipment, and vandalism in remote unmanned facilities. The robust construction combining die-cast aluminum housings, impact-resistant tempered glass lenses rated IK09 or higher, and secure mounting hardware ensures Explosion Proof Flood Lights maintain operational integrity despite the mechanical stresses inherent in industrial petroleum environments.

Long-Term Cost Analysis and Return on Investment

While premium Explosion Proof Flood Lights command higher initial acquisition costs compared to substandard alternatives, comprehensive lifecycle cost analysis reveals substantial economic advantages that justify the investment. Energy consumption represents the dominant operational expense over fixture lifespan—LED technology consumes 80-85% less electricity than HID systems it replaces, generating thousands of dollars in annual savings per fixture through reduced utility bills. Extended 50,000-hour LED lifespans compared to 10,000-hour HID lamps eliminate frequent lamp replacements requiring expensive maintenance crews, specialized equipment, hot work permits, and production disruptions in hazardous locations where accessing fixtures demands extensive safety protocols and operational shutdowns. Superior thermal management and premium components minimize unexpected failures that trigger emergency maintenance callouts at premium labor rates. Certifications and warranties from reputable manufacturers like Xi'an Razorlux protect against premature failures, provide replacement assurance, and demonstrate due diligence for insurance and regulatory compliance. Facilities calculating total cost of ownership including acquisition, installation, energy consumption, maintenance labor, replacement parts, and disposal costs over ten-year operational periods consistently find that premium Explosion Proof Flood Lights from established manufacturers deliver dramatically lower lifecycle costs despite higher upfront investments. Additionally, avoiding the catastrophic financial consequences of explosion incidents caused by non-compliant lighting—potential costs including loss of life, facility destruction, environmental remediation, regulatory penalties, litigation settlements, and reputation damage—represents incalculable value that transcends simple return on investment calculations and elevates proper lighting selection to fundamental risk management priority.

Quality Assurance and Manufacturing Excellence

Rigorous Testing Protocols Throughout Production

Xi'an Razorlux Optoelectronic Technology Co., Ltd. implements comprehensive quality control protocols throughout the manufacturing process to ensure every Explosion Proof Flood Light meets stringent safety and performance standards before shipment. The quality journey begins on precision assembly lines where skilled technicians construct fixtures following documented procedures that eliminate variations and defects. Each completed unit undergoes individual photometric testing using integrating sphere equipment that measures actual luminous output, beam distribution, color temperature, and color rendering index to verify compliance with published specifications. This photometric validation ensures customers receive fixtures delivering promised illumination characteristics rather than disappointing underperformance discovered after installation. Comprehensive aging tests subject all finished lights to extended operation at elevated temperatures, simulating years of field service to identify potential component failures before they occur in customer facilities. This burn-in process eliminates infant mortality failures while validating long-term reliability claims. Electrical safety testing verifies insulation resistance, ground continuity, and leakage current meet international standards. Environmental testing including ingress protection verification, salt spray exposure, thermal cycling, vibration resistance, and impact testing confirms housings withstand harsh industrial conditions. Only units successfully completing this rigorous multi-stage testing protocol receive quality certification and authorization for shipment. This uncompromising commitment to quality assurance differentiates reputable manufacturers from suppliers shipping untested products that fail prematurely in field service.

Protective Packaging and Global Logistics Solutions

Explosion Proof Flood Lights represent significant investments requiring protective packaging that ensures products arrive in perfect condition regardless of transportation method or destination. Xi'an Razorlux employs sophisticated packaging systems beginning with individual protection where each fixture receives wrapping in protective plastic bags before placement in custom cartons featuring precision-cut foam bases that cushion units and prevent movement during handling. Top foam layers incorporate dedicated compartments organizing mounting brackets, hardware, and accessories while providing additional cushioning protection. Heavy-duty packing tape and reinforced plastic strapping secure cartons against accidental opening or crushing damage. For customers requiring enhanced protection—particularly for overseas shipments, bulk orders, or destinations with challenging logistics infrastructure—optional wooden crate solutions provide military-grade protection ensuring fixtures survive transcontinental journeys unscathed. Comprehensive logistics services accommodate diverse customer requirements and urgency levels. International express services via DHL, FedEx, and UPS deliver small orders weighing 0.5kg to 300kg within 3-7 days, optimal for urgent projects and replacement parts under contracted express rates. Air freight provides economical solutions for shipments exceeding 300kg, reducing delivery to 5-10 days while offering significant cost savings compared to express services for heavier cargo. China-Europe Railway Express serves customers with 2CBM or 500KG+ shipments requiring delivery within 18-22 days, balancing speed and economy for large projects with flexible timelines. Ocean freight represents the most economical shipping method for non-urgent cargo, accommodating full container loads or less-than-container-load shipments with delivery spanning 15-50 days depending on destination ports. This comprehensive logistics infrastructure ensures customers receive their Explosion Proof Flood Lights safely, economically, and according to project schedules regardless of order size or global location.

Comprehensive Warranty and Technical Support Programs

Xi'an Razorlux backs its Explosion Proof Flood Lights with industry-leading warranty programs demonstrating confidence in product quality and commitment to long-term customer relationships. Standard 5-year warranty coverage protects customers against manufacturing defects, premature component failures, and performance degradation below published specifications, providing peace of mind and financial protection throughout the critical initial operational period. Responsive technical support teams provide 24/7 assistance addressing installation questions, troubleshooting operational issues, and recommending optimal solutions for challenging applications. This ongoing support relationship transforms transactions into partnerships where manufacturer expertise assists customers throughout product lifecycles. Pre-sales consultation services help customers select appropriate fixtures matching specific application requirements, navigating the complex decision matrix of wattage, beam patterns, mounting options, certifications, and environmental ratings. Custom sampling and prototyping programs allow customers to evaluate actual product quality and performance before committing to large orders, eliminating uncertainty and ensuring satisfaction. Detailed technical drawings, comprehensive product specifications, and professional installation guides support engineering teams during project planning and implementation phases. After-sales service extends beyond warranty obligations to include replacement parts availability ensuring facilities can maintain lighting systems long-term without obsolescence concerns. For complex installations or unique applications, on-site technical assistance provides hands-on expertise ensuring optimal system performance. This comprehensive support infrastructure differentiates manufacturers committed to customer success from vendors focused solely on transactional sales, creating lasting value that extends far beyond initial product acquisition.

Conclusion

Selecting the best Explosion Proof Flood Lights for oil and gas facilities demands careful evaluation of safety certifications, technical specifications, manufacturing quality, and long-term support. Premium solutions from Xi'an Razorlux deliver certified protection, superior performance, and exceptional value through advanced LED technology, robust construction, and comprehensive service programs that ensure safe, reliable illumination in the petroleum industry's most challenging environments.

Ready to upgrade your facility's hazardous location lighting with certified, high-performance solutions? As a leading China Explosion Proof Flood Lights manufacturer, Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers competitive China Explosion Proof Flood Lights wholesale pricing from our advanced China Explosion Proof Flood Lights factory. Whether you need Explosion Proof Flood Lights for sale for immediate projects or seeking the best Explosion Proof Flood Lights price for budget planning, our expert team provides customized solutions backed by comprehensive technical support, flexible OEM/ODM services, and proven quality with 3-5 year warranties. Contact our professional sales team today at sam@razorlux.com to discuss your specific requirements, request product samples, receive detailed quotations, and discover why safety-conscious organizations worldwide choose Razorlux as their trusted China Explosion Proof Flood Lights supplier for mission-critical petroleum applications that demand uncompromising reliability and performance.

References

1. National Fire Protection Association. NFPA 70: National Electrical Code - Article 500: Hazardous (Classified) Locations, Classes I, II, and III, Divisions 1 and 2. Author: NFPA Technical Committee on Hazardous Locations.

2. International Electrotechnical Commission. IEC 60079-0: Explosive Atmospheres - Part 0: Equipment - General Requirements. Author: IEC Technical Committee 31.

3. American Petroleum Institute. API RP 500: Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class I, Division 1 and Division 2. Author: API Electrical Equipment Subcommittee.

4. Illuminating Engineering Society. IES RP-29: Lighting for Outdoor Industrial Facilities Including Hazardous Locations. Author: IES Industrial Lighting Committee.

_1750326878398.png)