5 Reasons Explosion Proof Flood Lights Boost Industrial Efficiency

In hazardous industrial environments where volatile gases, combustible dust, and flammable vapors threaten operational safety every single day, inadequate lighting isn't just an inconvenience—it's a catastrophic risk that can lead to explosions, worker injuries, costly downtime, and regulatory violations. Explosion Proof Flood Lights have emerged as the critical solution that transforms dangerous workspaces into safe, productive environments while dramatically reducing energy costs and maintenance burdens. This comprehensive guide reveals five compelling reasons why explosion proof LED flood lights are revolutionizing industrial efficiency across oil refineries, chemical plants, petrochemical facilities, mining operations, and offshore platforms worldwide.

1. Enhanced Safety Standards Through Certified Explosion Proof Lighting Technology

ATEX and IECEx Certifications Guarantee Maximum Protection

Explosion Proof Flood Lights manufactured by Xi'an Razorlux Optoelectronic Technology Co., Ltd. meet the most stringent international safety certifications including ATEX, IECEx, UL, CUL, DLC, PSE, SAA, C-TICK, CQC, CE, and RoHS standards. These certifications ensure that every fixture is engineered to contain any internal spark or arc within a sealed enclosure, preventing ignition of surrounding explosive atmospheres in Class I Division 1 and Division 2 hazardous locations. The IP68 protection rating guarantees complete dust-tight sealing and protection against heavy water jets, making these lights ideal for offshore platforms and marine environments where salt spray and moisture pose constant threats.

Robust Construction Prevents Ignition Sources

The die-cast ADC12 aluminum housing with patent design provides exceptional durability while maintaining optimal heat dissipation through a 2.0mm aluminum PCB with heat index 2.5. This advanced thermal management system keeps LED chips operating at cool temperatures between -30°C to 50°C, preventing surface temperatures from reaching ignition points of flammable materials. The shock and vibration resistant tempered glass lens offers 95% light transmission while protecting internal components from mechanical impacts that could compromise safety in industrial settings where heavy machinery operates continuously.

Scientific Optical Design Eliminates Hazardous Glare

Anti-glare scientific optical reflector design in Explosion Proof Flood Lights creates focused, even, and comfortable illumination that enhances worker visibility without creating dangerous blind spots or excessive brightness that impairs judgment. This careful light distribution reduces workplace accidents by ensuring operators can clearly see equipment controls, warning signs, and potential hazards throughout their shifts, contributing directly to improved safety performance metrics and reduced insurance costs for industrial facilities.

2. Dramatic Energy Savings and Reduced Operating Costs with LED Technology

| Feature | Traditional HID Lighting | Explosion Proof LED Flood Lights | Cost Impact |

|---|---|---|---|

| Energy Consumption | 600W typical | 100W-180W range | 70-85% reduction |

| Lifespan | 10,000-15,000 hours | 50,000+ hours | 3-5x longer |

| Maintenance Frequency | Annual replacement | 5-year warranty | 80% less downtime |

| Heat Generation | Extremely high (1000°C+) | Minimal with thermal management | Lower cooling costs |

High Efficacy LED Chips Maximize Lumen Output

Razorlux Explosion Proof Flood Lights utilize high efficacy 700MA LED chips with low decay characteristics, delivering exceptional brightness while consuming minimal electricity. The original Bridgelux LED source provides high luminous efficacy ranging from 14,500 to over 64,000 lumens depending on the power option selected (30W, 80W, 100W, or 180W configurations). This superior performance allows facilities to replace outdated 600W metal halide or high pressure sodium fixtures with 100W LED equivalents, generating immediate return on investment through dramatically reduced electricity consumption that compounds savings month after month.

MEANWELL HLG Series Drivers Ensure Reliable Performance

The MEANWELL HLG series driver represents the highest level of power management technology available for industrial LED lighting applications. These drivers provide stable current regulation, surge protection up to 10kV, and thermal shutdown protection that extends component lifespan while maintaining consistent light output throughout the fixture's operational life. This reliability eliminates the frequent ballast failures common with traditional HID explosion proof lighting, reducing emergency maintenance calls and unplanned production interruptions that cost industrial facilities thousands of dollars per incident.

Long-Term Financial Benefits Beyond Energy Savings

When calculating total cost of ownership for Explosion Proof Flood Lights, industrial facilities discover that LED technology delivers value far beyond reduced electricity bills. The 50,000+ hour lifespan translates to approximately 15 years of operation at 10 hours daily use, eliminating repeated purchasing of replacement fixtures. The powder-coated surface treatment provides salt resistance and chemical resistance while preventing dust accumulation, reducing cleaning maintenance requirements. Additionally, the emergency power function developed by Razorlux allows fixtures to operate for two hours during power outages, maintaining critical safety lighting without expensive backup generator systems.

3. Superior Illumination Quality Increases Worker Productivity and Precision

Optimal Color Temperature Enhances Visual Acuity

Explosion Proof Flood Lights from Razorlux offer customizable color temperature options that significantly impact worker performance in industrial environments. The 5000K daylight white specification provides crisp, clear illumination that closely mimics natural sunlight, reducing eye strain during extended shifts and improving color recognition for quality control inspections. This superior light quality enables workers to identify subtle differences in materials, detect potential equipment problems early, and perform precision tasks with greater accuracy, directly contributing to reduced defect rates and improved production quality metrics.

Even Light Distribution Eliminates Dangerous Shadows

The scientific optical reflector design incorporated into Explosion Proof Flood Lights creates uniform light distribution across large industrial work areas, eliminating the harsh shadows and dark corners that compromise safety and productivity with traditional lighting systems. This even illumination pattern allows workers to move confidently through hazardous areas without visual adaptation delays when transitioning between light and dark zones. Facilities report measurably improved productivity when workers can clearly see their entire workspace simultaneously, reducing time wasted searching for tools, materials, or navigating around obstacles.

Instant-On Performance Supports Operational Flexibility

Unlike traditional HID explosion proof lights that require 5-15 minutes warm-up time before reaching full brightness, LED Explosion Proof Flood Lights provide instant illumination the moment power is applied. This immediate response enables facilities to implement motion sensor controls or scheduled lighting protocols that further reduce energy consumption without compromising safety. Workers arriving for shift changes can begin productive work immediately rather than waiting for lights to warm up, and emergency situations receive instant illumination when every second counts for evacuation or incident response procedures.

4. Minimal Maintenance Requirements Reduce Downtime and Labor Costs

| Maintenance Factor | Traditional Lighting | Explosion Proof LED Flood Lights | Impact on Operations |

|---|---|---|---|

| Replacement Frequency | 1-2 years | 5-10 years | 75% fewer shutdowns |

| Labor Hours Required | 4-6 hours per fixture | 0.5 hours per 5 years | 90% labor reduction |

| Specialized Tools Needed | Multiple | Standard mounting hardware | Simplified procedures |

| Safety Certifications | Annual recertification | Factory sealed units | Reduced compliance costs |

Extended Lifespan Eliminates Frequent Replacements

The combination of high-quality Bridgelux LED chips, advanced thermal management through the 2.0mm aluminum PCB, and robust ADC12 aluminum housing construction enables Razorlux Explosion Proof Flood Lights to operate continuously for 50,000+ hours with minimal lumen degradation. This exceptional lifespan means facilities can install lighting systems and essentially forget about them for the next decade, focusing maintenance resources on critical production equipment rather than constantly replacing failed fixtures. The 5-year warranty coverage provides additional peace of mind, protecting facility budgets from unexpected replacement costs.

Simplified Installation Process Reduces Implementation Costs

Explosion Proof Flood Lights feature versatile mounting options including surface mount, pendant mount, and adjustable brackets that accommodate diverse installation requirements without specialized tools or extensive structural modifications. The lightweight yet durable construction reduces installation time compared to heavy traditional fixtures, and the universal 100-277V input voltage compatibility eliminates the need for custom electrical configurations. Facilities can complete lighting upgrades during scheduled maintenance windows rather than requiring extended production shutdowns, minimizing revenue loss during implementation.

Reduced Environmental Impact Supports Sustainability Goals

LED Explosion Proof Flood Lights contain no mercury or hazardous materials, eliminating special disposal requirements and environmental liability associated with traditional lighting technologies. The dramatically reduced energy consumption directly decreases carbon footprint and supports corporate sustainability initiatives that increasingly influence customer purchasing decisions and regulatory compliance. Many industrial facilities discover that lighting upgrades contribute significantly toward achieving emissions reduction targets while simultaneously improving safety and reducing operating costs—a rare triple benefit in industrial operations.

5. Compliance with International Standards Ensures Global Market Access

Comprehensive Certification Portfolio Opens Worldwide Opportunities

Razorlux Explosion Proof Flood Lights carry an extensive certification portfolio including ATEX for European markets, UL and CUL for North American installations, PSE for Japan, SAA and C-TICK for Australia, CQC for China, and CE and RoHS for global compliance. This comprehensive certification coverage enables industrial companies to standardize lighting solutions across international operations rather than managing multiple product lines for different regulatory jurisdictions. The IP68 rating ensures reliable performance in the harshest marine and industrial environments from offshore oil platforms to chemical processing facilities worldwide.

Proven Performance in Demanding Applications

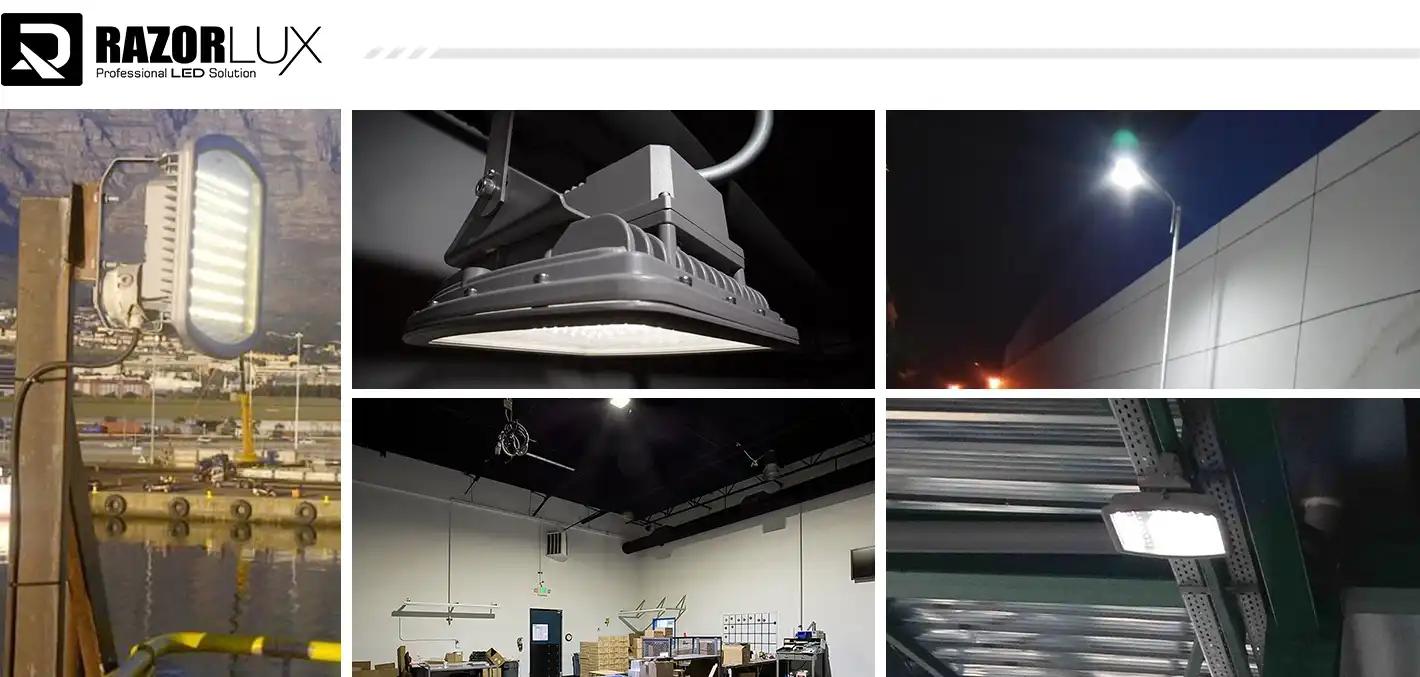

Xi'an Razorlux Optoelectronic Technology Co., Ltd. has supplied Explosion Proof Flood Lights to oil refineries, gas processing plants, chemical and petrochemical facilities, offshore platforms, mining operations, pharmaceutical manufacturing areas, paint spray booths, solvent storage facilities, grain elevators, flour mills, and aircraft hangars across Europe, North America, Southeast Asia, and beyond. This extensive application experience demonstrates the versatility and reliability of these fixtures in the most challenging industrial environments where failure is not an option.

Customization Capabilities Meet Specific Project Requirements

Razorlux offers flexible manufacturing capabilities allowing customization in wattage, color temperature, housing materials, mounting options, and control systems including 0-10V and DALI dimming integration. The company's in-house R&D team with over 10 industry experts and more than 200 patents covering LED Packaging, power control, and structural design enables rapid development of specialized solutions for unique industrial lighting challenges. OEM and ODM services allow equipment manufacturers and system integrators to create branded lighting solutions that meet specific market demands while leveraging Razorlux's proven explosion proof technology.

Conclusion

Explosion Proof Flood Lights represent a transformative investment for industrial facilities operating in hazardous environments, delivering exceptional safety performance, dramatic energy savings, superior illumination quality, minimal maintenance requirements, and global regulatory compliance. The combination of certified explosion proof construction, advanced LED technology, robust materials, and comprehensive warranties creates compelling value that extends far beyond initial purchase price to deliver measurable improvements in operational efficiency, worker safety, and total cost of ownership throughout the fixture's 15-year operational lifespan.

Ready to transform your industrial lighting with certified Explosion Proof Flood Lights? As a leading China Explosion Proof Flood Lights manufacturer, China Explosion Proof Flood Lights supplier, and China Explosion Proof Flood Lights factory, Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers competitive China Explosion Proof Flood Lights wholesale pricing on Explosion Proof Flood Lights for sale with transparent Explosion Proof Flood Lights price quotations. Contact our expert team today at sam@razorlux.com to receive customized samples, detailed technical drawings, and comprehensive project consultation for your specific hazardous location lighting requirements. Bookmark this resource for future reference, and reach out whenever lighting challenges arise—we're here to illuminate your path to safer, more efficient industrial operations.

References

1. National Fire Protection Association (NFPA). "NFPA 70: National Electrical Code - Requirements for Hazardous Locations." NFPA Standards Council.

2. International Electrotechnical Commission (IEC). "IECEx Certification Scheme for Explosive Atmospheres - Equipment Protection Standards." IEC Technical Committee.

3. Illuminating Engineering Society (IES). "Industrial Lighting Design Guidelines for Hazardous Location Applications." IES Technical Reports Division.

4. American Petroleum Institute (API). "Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities." API Safety Standards Committee.

VIEW MOREled football field lights

VIEW MOREled football field lights VIEW MOREDimmable Outdoor Led Flood Lights

VIEW MOREDimmable Outdoor Led Flood Lights VIEW MOREDimmable Led Flood Lights Outdoor

VIEW MOREDimmable Led Flood Lights Outdoor VIEW MOREWaterproof Floodlight

VIEW MOREWaterproof Floodlight VIEW MOREBest Marine Led Flood Lights

VIEW MOREBest Marine Led Flood Lights VIEW MOREAluminum IP65 Led High Mast Light 1000W RoHS Led Baseball Field Lights

VIEW MOREAluminum IP65 Led High Mast Light 1000W RoHS Led Baseball Field Lights VIEW MORE300W Floodlight

VIEW MORE300W Floodlight VIEW MOREOutdoor Dimmable Flood Lights

VIEW MOREOutdoor Dimmable Flood Lights

_1750326878398.png)