What to Look for in Construction Site Flood Lights: A Buyer’s Guide

Picture this: your construction crew is racing against a tight deadline, but darkness falls before critical work is complete. Without adequate lighting, productivity plummets, safety risks multiply, and costly project delays become inevitable. Choosing the right Construction Site Flood Lights is not just about brightness—it's about ensuring worker safety, maintaining project timelines, and optimizing your long-term operational costs. This comprehensive buyer's guide will walk you through the essential factors to consider when selecting Construction Site Flood Lights, helping you make an informed decision that protects your workers, your budget, and your project success.

Essential Technical Specifications for Construction Site Flood Lights

Understanding the technical specifications of Construction Site Flood Lights is fundamental to making a purchasing decision that delivers both immediate performance and long-term value. The construction environment demands lighting solutions that go far beyond basic illumination—they must withstand harsh conditions, provide consistent output, and meet strict safety standards while keeping energy costs manageable.

Power Requirements and Voltage Compatibility

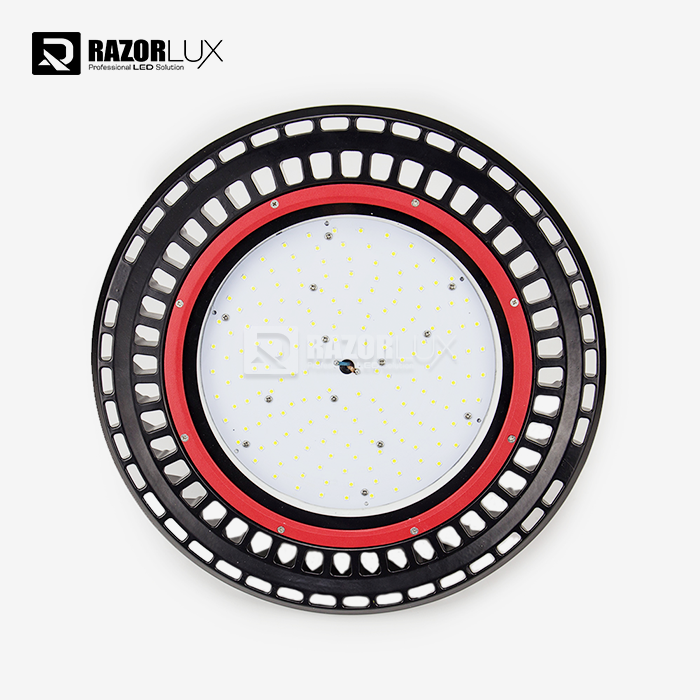

When evaluating Construction Site Flood Lights, power consumption and voltage compatibility represent critical factors that directly impact your operational costs and installation flexibility. Modern high-performance models like Razorlux's RGL-1000A deliver an impressive 1000W total power consumption, with 900W dedicated to LEDs and 100W to the driver system. This configuration provides exceptional illumination while replacing traditional HID lamps that would consume 2200-2500W for comparable output. The voltage flexibility is equally important—professional-grade Construction Site Flood Lights should accommodate wide input ranges such as AC 80-305Vac or DC 100-400Vdc, ensuring compatibility with various power sources including generators, temporary power distribution systems, and permanent installations. This adaptability becomes particularly valuable on construction sites where power infrastructure may be temporary or inconsistent. Additionally, look for fixtures with power factors of ≥0.98 and total harmonic distortion (THD) below 10 percent, as these specifications ensure efficient power utilization and minimize electrical system stress. The ability to operate across extreme temperature ranges, typically from -40°C to 60°C, further demonstrates the robustness required for demanding construction environments where weather conditions can vary dramatically throughout a project timeline.

Lumen Output and Illumination Efficiency

The lumen output of Construction Site Flood Lights directly determines the coverage area and visibility levels achievable on your worksite, making it one of the most critical specifications to evaluate. Professional construction applications require substantial illumination—premium fixtures can deliver 130,000 lumens or more, providing the brightness necessary to safely illuminate large work zones even during nighttime operations. However, raw lumen numbers tell only part of the story; lamp efficiency, measured in lumens per watt, reveals the true value proposition. Advanced Construction Site Flood Lights achieve efficiencies of 130LM/W or higher, significantly outperforming older metal halide or halogen technologies that waste substantial energy as heat rather than light. The stable flux rating after one hour of operation is another crucial consideration, as many fixtures experience significant lumen depreciation during warm-up or extended use. Quality Construction Site Flood Lights maintain consistent output throughout their operational period, ensuring workers never experience dangerous lighting fluctuations during critical tasks. The color rendering index (CRI) also deserves attention—ratings of Ra>75 provide adequate color differentiation for most construction work, while Ra>80 or Ra>90 options enable more precise color identification for finishing work or quality inspections. When combined with appropriate beam angles ranging from 40° to 140°, these specifications ensure Construction Site Flood Lights deliver not just brightness, but usable, task-appropriate illumination that enhances both productivity and safety across your entire worksite.

Ingress Protection and Durability Standards

Construction sites present some of the harshest environmental conditions any lighting equipment will face, making ingress protection ratings absolutely essential when selecting Construction Site Flood Lights. The IP (Ingress Protection) rating system provides standardized measurements of a fixture's resistance to solid particles and liquids—for construction applications, minimum ratings of IP65 are recommended, with IP67 providing superior protection against dust ingress and temporary water immersion. Professional-grade Construction Site Flood Lights feature IP65/IP67 ratings as standard, ensuring they continue operating reliably despite exposure to construction dust, concrete spray, rain, and temporary flooding. The IK rating, which measures impact resistance, is equally important; IK10-rated fixtures withstand impacts of 20 joules, equivalent to 5kg dropped from 40cm, protecting against accidental strikes from tools, equipment, or debris. Beyond these ratings, examine the housing material and construction—marine-grade aluminum with powder coating provides excellent corrosion resistance and heat dissipation, while stainless steel brackets ensure mounting reliability even in harsh weather conditions. Construction Site Flood Lights designed for demanding environments also incorporate advanced thermal management systems that prevent LED degradation due to heat buildup, extending operational life beyond 50,000 hours. The working humidity tolerance, typically 10-95 percent, ensures consistent performance across diverse climatic conditions from arid deserts to humid coastal regions. When evaluating durability, also consider the warranty terms—reputable manufacturers offer 5-year warranties on LED modules and drivers, with some extending housing warranties to 10 years, demonstrating confidence in their Construction Site Flood Lights' longevity and providing protection for your investment.

Critical Performance Features for Construction Applications

Beyond basic technical specifications, Construction Site Flood Lights must deliver specific performance characteristics that address the unique challenges of construction environments. These features separate professional-grade solutions from consumer products, ensuring your lighting investment delivers reliable performance throughout demanding project lifecycles.

Beam Angle and Light Distribution Capabilities

| Beam Angle | Coverage Pattern | Ideal Construction Application | Mounting Height |

|---|---|---|---|

| 40° | Narrow concentrated beam | High-rise construction, tower crane operation, focused task lighting | 25-40m |

| 60° | Medium spread pattern | General construction sites, equipment yards, loading zones | 15-25m |

| 120° | Wide area coverage | Large open construction areas, excavation sites, parking areas | 8-15m |

| 140°×60° | Asymmetric distribution | Perimeter lighting, roadway work zones, linear construction sites | 10-20m |

The beam angle selection for Construction Site Flood Lights fundamentally determines how effectively your lighting investment covers the required work area. Unlike indoor applications where uniform distribution is straightforward, construction sites feature varying ceiling heights, obstacles, and work zone layouts that demand flexible optical solutions. Premium Construction Site Flood Lights offer multiple beam angle options—40° narrow beams concentrate intense illumination on specific high-detail work areas or vertically illuminate tall structures, while 120° wide-angle configurations provide broad coverage for open work zones. The patented multi-function design found in advanced fixtures like Razorlux's offerings allows contractors to select the optimal beam angle for each installation point, maximizing coverage efficiency while minimizing the total number of fixtures required. Asymmetric beam patterns, such as 140°×60° configurations, prove particularly valuable for linear work zones like roadway construction or perimeter security, where traditional round beam patterns would waste light beyond the work area. When evaluating beam angles, consider not only the current project requirements but also future applications—Construction Site Flood Lights with field-adjustable optics provide superior flexibility for contractors managing diverse project portfolios. The light distribution uniformity also matters significantly; premium fixtures achieve consistent foot-candle levels across the illuminated area without creating dangerous hot spots or shadows where accidents frequently occur. Understanding OSHA requirements for minimum illumination levels—typically 5 foot-candles for general construction areas and 10+ foot-candles for detailed work—helps you select appropriate beam angles and mounting configurations that ensure regulatory compliance while optimizing worker safety and productivity across all construction site zones.

Color Temperature and Rendering Quality

The color temperature of Construction Site Flood Lights significantly impacts worker comfort, visual acuity, and the ability to accurately identify materials and potential hazards in construction environments. Measured in Kelvin (K), color temperature determines whether light appears warm (yellowish) or cool (bluish-white), with construction applications typically benefiting from temperatures between 4000K and 6000K. Professional Construction Site Flood Lights offer adjustable color temperatures ranging from 2700K to 6500K, allowing contractors to optimize lighting for specific tasks and environmental conditions. The 5000K setting, often called "daylight white," has become the industry standard for construction applications because it closely mimics natural daylight, reducing eye strain during extended work shifts and improving workers' ability to distinguish colors and surface details accurately. However, certain specialized applications benefit from alternative temperatures—concrete finishing work may require cooler 6000K+ temperatures to reveal subtle surface imperfections, while welding zones benefit from slightly warmer temperatures that reduce glare from reflective surfaces. The color rendering index (CRI) works in conjunction with color temperature to determine overall visual quality. Construction Site Flood Lights with CRI ratings of Ra>75 provide adequate color differentiation for most construction tasks, but Ra>80 or Ra>90 options significantly enhance workers' ability to identify material quality, detect defects, and distinguish color-coded safety markings. This becomes particularly crucial for electrical work, plumbing installations, and finishing operations where precise color identification impacts work quality and safety compliance. Advanced Construction Site Flood Lights incorporate sophisticated LED chip technology and optical design to maintain consistent color temperatures throughout the operational lifespan, preventing the color shift that plagued older metal halide fixtures as they aged. When selecting color temperature, consider the predominant work activities, surrounding environmental lighting, and worker preferences—some crews perform better under cooler temperatures that promote alertness, while others prefer warmer tones that feel more comfortable during overnight shifts in cold weather conditions.

Mounting Flexibility and Installation Options

Construction Site Flood Lights must accommodate diverse installation requirements, from temporary job site setups to permanent infrastructure installations, making mounting flexibility a crucial selection criterion. Professional-grade fixtures provide multiple mounting configurations including yoke mounts for precise angle adjustment, trunnion mounts for elevated applications, and slip-fitter options for standard pole mounting systems. The adjustable bracket system, often constructed from stainless steel for corrosion resistance, should offer 180-degree rotation and secure locking mechanisms that maintain positioning despite vibration from nearby construction equipment. Dimension specifications matter significantly for installation planning—a fixture like Razorlux's RGL-1000A, measuring 671×405×379mm and weighing 30kg, requires substantial mounting infrastructure and careful consideration of wind loading calculations for elevated installations. Construction Site Flood Lights designed for crane mounting or light tower applications incorporate additional reinforcement and anti-vibration features that prevent fixture loosening during equipment operation. The modular design approach found in premium fixtures allows for easy maintenance and component replacement without complete fixture removal, minimizing downtime when service becomes necessary. Cable entry configurations should support various conduit sizes and provide strain relief to prevent wiring damage from movement or environmental exposure. For temporary construction applications, quick-mount systems with tool-free adjustment capabilities significantly reduce installation time and labor costs, while permanent installations benefit from more robust fixed-mount solutions with enhanced weather sealing. Consider the mounting height requirements for your specific application—Construction Site Flood Lights intended for ground-level work zones require different optical and mounting configurations than those designed for high-mast installations illuminating large infrastructure projects. The net weight of 30kg for high-output fixtures necessitates structural engineering verification for some mounting applications, particularly when installing multiple units on temporary structures or mobile equipment. Proper mounting not only ensures optimal light distribution but also protects workers from potential fixture failures caused by inadequate support or vibration-induced loosening during construction operations.

Operational Efficiency and Cost Considerations

Understanding the total cost of ownership for Construction Site Flood Lights extends far beyond the initial purchase price, encompassing energy consumption, maintenance requirements, and operational lifespan. Smart buyers evaluate these factors comprehensively to identify solutions that deliver superior long-term value rather than simply selecting the lowest-priced option.

Energy Consumption and Operational Savings

| Lighting Technology | Power Consumption | Annual Energy Cost (4000h/year @ $0.12/kWh) | Lifespan | Replacement Frequency |

|---|---|---|---|---|

| Traditional Metal Halide | 2200-2500W | $1,056 - $1,200 | 10,000-15,000 hours | Every 2.5-3.75 years |

| Older LED Technology | 1200-1500W | $576 - $720 | 30,000-40,000 hours | Every 7.5-10 years |

| Advanced LED (Razorlux RGL-1000A) | 1000W | $480 | 50,000+ hours | Every 12.5+ years |

| Energy Savings vs Metal Halide | 1200-1500W reduction | $576-$720 annually | 35,000-40,000 hours extended life | 75-80% fewer replacements |

The energy efficiency of Construction Site Flood Lights dramatically impacts long-term operational costs, making this specification crucial for projects with extended timelines or permanent installations. Advanced LED Construction Site Flood Lights consume 55-60 percent less energy than equivalent metal halide fixtures while delivering superior lumen output and light quality. A typical 1000W LED fixture replacing a 2200W metal halide unit saves approximately 1200W per operating hour—when you calculate this across thousands of operational hours over a construction project's duration, the cumulative energy savings become substantial. Construction projects operating lights for 4000 hours annually can save $720 per fixture per year compared to traditional lighting technologies, with these savings continuing throughout the fixture's operational life. The power factor rating, ideally ≥0.98 for professional Construction Site Flood Lights, ensures maximum utilization of supplied electrical power while minimizing reactive power losses that increase utility costs without providing additional illumination. Advanced Meanwell power supplies and sophisticated driver circuitry maintain consistent efficiency across the full input voltage range, preventing power waste due to voltage fluctuations common in temporary construction power distribution systems. The thermal management system in premium Construction Site Flood Lights also contributes to efficiency—by maintaining optimal LED junction temperatures, these systems prevent the efficiency degradation that occurs when LED chips overheat during extended operation. Some advanced Construction Site Flood Lights now incorporate emergency backup power functions that enable continued operation for up to two hours during power outages, protecting project timelines and worker safety without requiring expensive backup generator capacity. When calculating operational savings, consider not only direct energy costs but also reduced infrastructure requirements—highly efficient fixtures may allow smaller generator sizing, reduced electrical distribution capacity, and lower cooling loads in enclosed spaces, all contributing to comprehensive cost reductions across your construction project's electrical systems.

Maintenance Requirements and Warranty Protection

The maintenance demands of Construction Site Flood Lights directly impact both operational costs and project continuity, making low-maintenance designs with comprehensive warranty coverage essential for professional contractors. Traditional metal halide and halogen fixtures require frequent lamp replacements—typically every 10,000-15,000 hours—along with periodic ballast servicing, creating recurring labor costs and productivity interruptions. Professional LED Construction Site Flood Lights eliminate these maintenance burdens with operational lifespans exceeding 50,000 hours, effectively providing maintenance-free operation for most construction project durations. The modular design approach used in premium fixtures enables rapid component replacement when service eventually becomes necessary—LED modules, drivers, and optical components can be individually replaced without complete fixture disposal, reducing long-term ownership costs. Rigorous quality control processes, including assembly line inspections, photometric testing, aging tests, and stress testing under simulated extreme conditions, ensure Construction Site Flood Lights arrive ready for demanding applications without early-life failures. The warranty structure reveals manufacturers' confidence in their products—comprehensive coverage including 5-year warranties on LED modules and drivers, with 10-year housing warranties, demonstrates commitment to product quality and customer protection. Xi'an Razorlux Optoelectronic Technology, with over 20 years of LED lighting expertise and more than 200 patents covering LED Packaging, power control, and structural design, exemplifies the research-driven approach that produces Construction Site Flood Lights capable of surviving harsh construction environments while maintaining performance specifications. After-sales support services including technical consultation, installation guidance, maintenance advice, and spare parts availability ensure contractors can quickly resolve any issues without extended downtime. The comprehensive inspection stages throughout manufacturing, combined with strict component selection and testing protocols, minimize the likelihood of field failures that disrupt construction schedules. When evaluating warranty terms, examine not only the duration but also coverage specifics—some warranties exclude damage from improper installation or environmental factors beyond normal construction site conditions. Premium manufacturers support their Construction Site Flood Lights with responsive technical teams that understand real-world construction challenges and can provide practical solutions rather than simply processing warranty claims. The packaging and transportation protection also impacts long-term reliability—Construction Site Flood Lights should arrive with individual foam protection, accessory compartments, sealed cartons reinforced with strapping, and optional wooden crate solutions for bulk shipments ensuring products reach job sites undamaged and ready for immediate deployment.

Return on Investment Analysis

Calculating the complete return on investment for Construction Site Flood Lights requires analyzing both immediate project benefits and long-term value accumulation across multiple applications. The initial purchase price represents only a fraction of total ownership costs—energy consumption, maintenance labor, replacement frequency, and productivity impacts all contribute to comprehensive financial analysis. Professional Construction Site Flood Lights typically cost 2-3 times more than basic consumer-grade fixtures initially, but this premium pays for itself through reduced operational expenses and superior performance reliability. Consider a typical construction project requiring 20 flood lights operating 4000 hours annually: advanced LED fixtures consuming 1000W versus traditional 2200W metal halide units save approximately 14,400 kWh annually per fixture, totaling 288,000 kWh for the complete installation. At $0.12 per kWh, this represents $34,560 in annual energy savings—enough to recover the initial investment premium within 1-2 years depending on specific fixture pricing. The maintenance cost differential amplifies these savings—eliminating lamp replacement labor for 20 fixtures every 2-3 years saves thousands in labor costs and reduces productivity disruptions. Construction Site Flood Lights with 50,000+ hour lifespans effectively eliminate replacement costs for most construction projects, while traditional technologies require multiple replacement cycles during the same period. The productivity and safety improvements from superior illumination quality represent additional ROI that's harder to quantify but potentially more valuable—reducing accident rates, enabling extended work shifts, improving work quality, and maintaining schedule adherence all contribute substantial financial benefits. Projects in remote locations or those requiring extensive logistics for equipment delivery gain additional value from reduced maintenance visits and longer replacement intervals. The certification compliance offered by professional Construction Site Flood Lights—including UL, RMRS, TUV, CE, SAA, RoHS, DLC, and CB certifications—ensures acceptance across international markets and compliance with varying regulatory requirements, protecting contractors from costly retrofitting or replacement to meet local standards. The customization capabilities available through manufacturers like Razorlux, including OEM/ODM services, wattage modifications, color temperature adjustments, and control system integration, enable contractors to optimize Construction Site Flood Lights precisely for each project's requirements rather than settling for generic off-the-shelf solutions that compromise performance or waste capacity. When calculating ROI, also consider the disposal and environmental compliance costs for traditional lighting technologies versus LED solutions—the absence of mercury and other hazardous materials in LED Construction Site Flood Lights simplifies end-of-life disposal while supporting corporate sustainability initiatives.

Conclusion

Selecting the right Construction Site Flood Lights requires balancing technical specifications, performance features, and long-term cost considerations to identify solutions that enhance safety, productivity, and profitability across demanding construction environments. By prioritizing high-efficiency LED technology with robust ingress protection, flexible mounting options, and comprehensive warranty coverage, contractors can ensure their lighting investments deliver reliable performance throughout extended project timelines while minimizing operational costs and maintenance disruptions.

Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready to support your construction lighting needs with over two decades of LED innovation, 200+ patents, and proven expertise across marine, industrial, and heavy-duty applications. Our Construction Site Flood Lights combine unparalleled durability, exceptional energy efficiency, and customizable solutions backed by rigorous quality control and comprehensive after-sales support. Whether you're seeking a trusted China Construction Site Flood Lights manufacturer, evaluating China Construction Site Flood Lights suppliers for competitive pricing, or researching China Construction Site Flood Lights factories with wholesale capabilities, Razorlux delivers Construction Site Flood Lights for sale that meet the highest international standards. Our Construction Site Flood Lights price points reflect exceptional value through superior performance, extended lifespans, and reduced operational costs. With mature R&D teams, GMP-certified manufacturing, extensive inventory, complete international certifications, and professional sales support, we ensure every customer receives the right product with the right specifications delivered on time. Contact our expert team at sam@razorlux.com today to discuss your specific requirements and discover how our Construction Site Flood Lights can illuminate your success.

References

1. Illuminating Engineering Society (IES). "Recommended Practice for Lighting Construction Sites." IES RP-21-22. New York: Illuminating Engineering Society, 2022.

2. Occupational Safety and Health Administration (OSHA). "Safety and Health Regulations for Construction: Illumination Requirements." 29 CFR 1926.56. Washington, DC: U.S. Department of Labor, 2024.

3. National Electrical Manufacturers Association (NEMA). "LED Lighting Systems Performance Specification for Outdoor Applications." NEMA SSL 7A-2015. Rosslyn, VA: NEMA, 2015.

4. Department of Energy, Office of Energy Efficiency and Renewable Energy. "Solid-State Lighting Program: LED Lighting Facts." Washington, DC: U.S. Department of Energy, 2024.

5. International Commission on Illumination (CIE). "Guide to the Lighting of Outdoor Work Areas." CIE 112-1994. Vienna, Austria: Commission Internationale de l'Éclairage, 1994.

VIEW MOREworkshop light fixtures

VIEW MOREworkshop light fixtures VIEW MOREbasketball court light fixture

VIEW MOREbasketball court light fixture VIEW MOREvolleyball court lights

VIEW MOREvolleyball court lights VIEW MOREbasketball court flood lights

VIEW MOREbasketball court flood lights VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MORELED softball field lighting high mast flood light systems

VIEW MORELED softball field lighting high mast flood light systems VIEW MORELed Bay Lighting Warehouse

VIEW MORELed Bay Lighting Warehouse VIEW MOREHigh Voltage Flood Lights

VIEW MOREHigh Voltage Flood Lights

_1750326878398.png)