Top Rated Construction Site Flood Lights for Harsh Environments

Picture this: a critical construction deadline looms, but your team struggles with inadequate lighting in dusty, rain-soaked conditions while your old fixtures fail one after another. Construction Site Flood Lights designed for harsh environments solve these exact challenges by delivering reliable, high-performance illumination that withstands extreme weather, temperature fluctuations, and demanding jobsite conditions. This comprehensive guide reveals how top-rated Construction Site Flood Lights enhance safety, boost productivity, and reduce downtime through advanced LED technology, military-grade durability, and intelligent features that transform even the most challenging work environments into well-lit, efficient spaces.

Essential Features of Industrial Construction Site Flood Lights

High Lumen Output and Energy Efficiency for Maximum Performance

Modern Construction Site Flood Lights must deliver exceptional brightness while maintaining energy efficiency to meet the demanding requirements of large-scale projects. The most advanced models provide 130,000 lumens with only 1000W power consumption, achieving remarkable 130LM/W lamp efficiency that dramatically reduces operational costs compared to traditional HID fixtures consuming 2200-2500W for equivalent output. This energy efficiency becomes crucial for construction projects operating around the clock, where lighting expenses can significantly impact overall project budgets. Professional-grade Construction Site Flood Lights incorporate sophisticated thermal management systems using aluminum housing with powder coating that dissipates heat effectively, ensuring consistent performance throughout 50,000+ hour lifespans without degradation. The intelligent power supply systems, such as Meanwell drivers, maintain stable output even when input voltage fluctuates between 80-305Vac or extends to DC ranges of 100-800Vdc, making these lights compatible with diverse power sources found on construction sites worldwide including generators, temporary power distribution systems, and alternative energy solutions.

Weather-Resistant Construction for Extreme Environmental Conditions

Top-rated Construction Site Flood Lights feature IP65 and IP67 ratings that guarantee complete protection against dust ingress and high-pressure water jets, essential for jobsites experiencing rain, snow, dust storms, and humidity extremes. The robust construction combines marine-grade anti-corrosion coatings with stainless steel brackets that resist rust and degradation even in coastal environments or industrial zones with chemical exposure. These fixtures operate reliably across temperature ranges from -40°C to 60°C (-40°F to 140°F), ensuring uninterrupted performance whether deployed in Arctic construction projects or desert infrastructure developments. The IK10 impact resistance rating means Construction Site Flood Lights withstand severe mechanical impacts equivalent to 20 joules of force, protecting internal components from falling tools, equipment collisions, and debris strikes common on active worksites. Advanced sealing technology prevents moisture penetration while maintaining heat dissipation capabilities, and the Class I insulation ensures electrical safety for ground crews working in wet conditions or during emergency response situations requiring immediate deployment without extensive safety protocols.

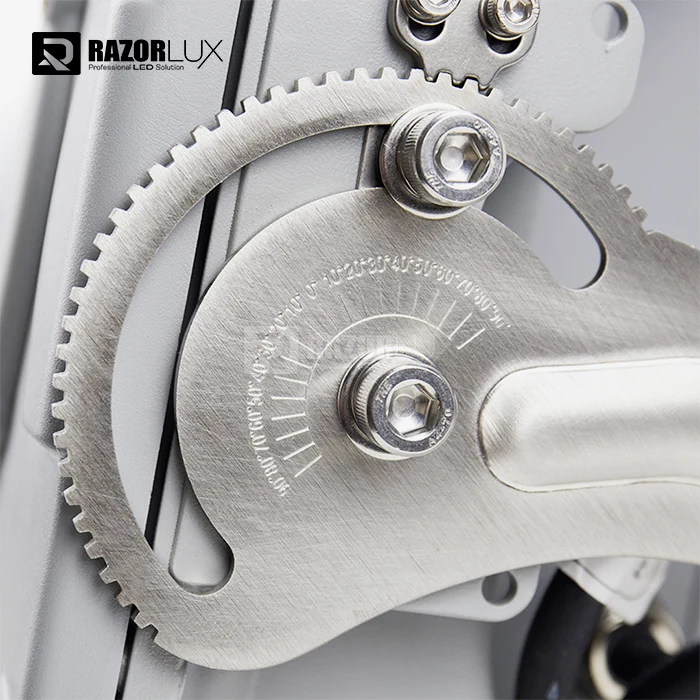

Versatile Beam Angles and Mounting Solutions for Site Optimization

Professional Construction Site Flood Lights offer multiple beam angle options including 40°, 60°, 120°, and asymmetric 140°x60° configurations that enable precise light distribution matching specific site layouts and task requirements. Narrow 40° beams concentrate illumination for tower cranes and elevated work platforms requiring focused distant lighting, while wide 120° angles provide broad area coverage for ground-level activities, equipment staging areas, and perimeter security. The patented multi-function mounting systems accommodate diverse installation scenarios from temporary light towers to permanent building-mounted fixtures, utilizing adjustable stainless steel brackets that withstand repeated repositioning without loosening or corroding. Construction Site Flood Lights weighing approximately 30kg offer stability against wind loads while remaining manageable for two-person installation teams using standard lifting equipment. The modular design facilitates quick replacement of components if damage occurs, minimizing downtime since maintenance crews can swap LED modules, drivers, or brackets without replacing entire fixtures, significantly reducing long-term operational costs and eliminating the productivity losses associated with extended repair periods.

Comparing Construction Site Lighting Solutions and Performance Standards

Performance Specifications of Leading Construction Site Flood Lights

| Specification | Standard Range | Premium Performance | Razorlux RGL-1000A |

|---|---|---|---|

| Rated Power | 400-800W | 800-1200W | 1000W (LEDs: 900W + Driver: 100W) |

| Lumen Output | 40,000-80,000 | 100,000-140,000 | 130,000lm (5700K after 1 hour) |

| Lamp Efficiency | 100-120 LM/W | 120-140 LM/W | 130 LM/W |

| Color Temperature | 4000-5000K | 2700-6500K | 2700-6500K (Customizable) |

| Beam Angle Options | 60°, 90° | 40°, 60°, 120° | 40°, 60°, 120°, 140°x60° |

| IP Rating | IP65 | IP65/IP67 | IP65 (Upgradeable to IP67) |

| Working Temperature | -20°C to 50°C | -40°C to 60°C | -40°C to 60°C |

| Input Voltage Range | 120-277Vac | 80-305Vac | AC: 80-305Vac / DC: 100-800Vdc |

| Warranty Period | 3 Years | 5 Years | LED & Driver: 5 Years / Housing: 10 Years |

The comparison demonstrates how premium Construction Site Flood Lights outperform standard models through superior efficiency, wider operating parameters, and extended warranty coverage that reduces total cost of ownership over project lifecycles. The ability to accept both AC and DC input voltages with such wide ranges makes advanced Construction Site Flood Lights compatible with unstable power sources common on developing infrastructure projects, remote mining operations, and emergency response situations where grid power remains unavailable. Color rendering index (CRI) ratings above Ra75, with options reaching Ra90, ensure accurate color perception critical for quality control inspections, safety hazard identification, and precision tasks requiring workers to distinguish between similar materials or identify color-coded systems. The substantial lumen maintenance throughout the rated 50,000-hour lifespan means Construction Site Flood Lights maintain consistent illumination levels without the dramatic degradation experienced by traditional metal halide or high-pressure sodium fixtures that lose 30-50% of initial output within the first 10,000 hours.

Installation Requirements and Site Preparation Guidelines

Proper installation of Construction Site Flood Lights begins with comprehensive site assessment identifying critical work zones, access routes, equipment staging areas, and perimeter boundaries requiring illumination according to OSHA standards and local safety regulations. Professional lighting designers calculate required foot-candle levels typically ranging from 10-20 for general construction activities to 50-100 for detailed tasks such as welding, electrical work, and precision equipment operation. The strategic placement of Construction Site Flood Lights considers mounting heights between 20-80 feet depending on beam angles and coverage requirements, with higher mounting positions suitable for wide-angle fixtures providing general area lighting while lower mounting heights work better for task-specific illumination using narrow beam concentrations. Electrical infrastructure must support the power requirements through properly rated circuit breakers, weather-resistant junction boxes, and cabling sized to handle the total wattage plus 25% safety margin accounting for voltage drop over cable runs extending hundreds of feet across large construction sites. Structural supports including light towers, building facades, crane booms, and temporary scaffolding require engineering verification ensuring adequate load capacity for fixture weights plus wind loading factors, particularly critical for deployments in hurricane-prone regions or areas experiencing severe weather events where improperly secured Construction Site Flood Lights become dangerous projectiles.

Safety Standards and Regulatory Compliance Requirements

Construction Site Flood Lights must meet stringent international certification standards including UL listing for North American markets, CE marking for European Union compliance, SAA certification for Australian deployment, and DLC qualification enabling utility rebate eligibility that significantly offsets initial investment costs. The fixtures undergo rigorous testing protocols verifying electromagnetic compatibility (EMC) ensuring they do not interfere with radio communications, safety systems, or electronic equipment operating on construction sites including two-way radios, crane control systems, and surveying instruments. Low total harmonic distortion (THD) below 10% prevents power quality issues that could damage sensitive electronic equipment or trip circuit protection devices, while power factor ratings exceeding 0.98 maximize electrical efficiency and minimize utility demand charges for large installations consuming substantial power. Construction Site Flood Lights certified to Class I insulation standards provide essential safety grounding preventing electric shock hazards particularly critical in wet environments or when fixtures contact metallic structures during installation or maintenance activities. RoHS compliance ensures fixtures contain no hazardous materials simplifying end-of-life disposal and meeting environmental regulations in jurisdictions with strict electronic waste management requirements, while the long operational lifespans reduce landfill impact by eliminating frequent replacement cycles associated with conventional lighting technologies requiring disposal every 5,000-10,000 hours.

Advanced Technologies in Modern Construction Site Flood Lights

Smart Control Systems and Energy Management Features

Contemporary Construction Site Flood Lights integrate intelligent control capabilities including 0-10V analog dimming and DALI (Digital Addressable Lighting Interface) protocols enabling precise light level adjustments matching ambient conditions, activity schedules, and specific task requirements throughout project timelines. Automated photocell sensors detect ambient light levels triggering automatic activation at dusk and deactivation at dawn, eliminating wasted energy during daylight hours while ensuring reliable illumination becomes available exactly when needed without manual intervention. Motion sensor integration allows Construction Site Flood Lights to operate at reduced output levels during unoccupied periods then instantly ramp to full brightness detecting personnel movement, enhancing security while dramatically reducing energy consumption during overnight hours when sites remain largely vacant except for security patrols. Centralized control systems enable facility managers to monitor, schedule, and adjust multiple Construction Site Flood Lights simultaneously through wireless networks or hardwired DMX systems, providing real-time status updates on fixture health, energy consumption, and operational hours facilitating predictive maintenance scheduling before failures disrupt construction activities. The emergency backup power function represents a critical safety innovation allowing Construction Site Flood Lights to operate for two hours during power outages using integrated battery systems, ensuring worker safety during evacuations and enabling emergency response activities in situations where primary power becomes unavailable due to equipment failures, severe weather events, or accidents requiring immediate site access.

Thermal Management and Component Longevity Optimization

Superior thermal management systems distinguish premium Construction Site Flood Lights through engineered heat sinks featuring optimized fin geometries, surface treatments, and airflow designs that maintain LED junction temperatures below critical thresholds where output degradation and premature failures occur. The aluminum housing material provides excellent thermal conductivity while the powder coating finish enhances corrosion resistance without impeding heat dissipation, and the strategic placement of driver components separates heat-generating elements preventing thermal coupling that could accelerate degradation of sensitive electronics. Advanced LED chip selection prioritizes proven technologies from leading manufacturers combined with optimized drive currents that balance maximum light output against operating temperatures and long-term reliability, with conservative designs operating LEDs at 70-80% of maximum rated current extending practical lifespans beyond 70,000 hours before reaching L70 depreciation points. Construction Site Flood Lights employ high-quality components including capacitors rated for extended temperature ranges, optically clear tempered glass lenses resistant to impacts and thermal shock, and sealed driver compartments protecting electronics from moisture infiltration and contamination. The modular construction philosophy enables selective replacement of specific components rather than complete fixture disposal when individual elements reach end-of-life, significantly reducing ownership costs while minimizing environmental impact through reduced waste generation and efficient resource utilization aligned with sustainable construction practices increasingly mandated by green building certification programs and corporate environmental responsibility initiatives.

Customization Options and Application-Specific Configurations

Leading manufacturers of Construction Site Flood Lights offer extensive customization capabilities enabling projects to specify exact wattage requirements, select color temperatures optimizing visibility for specific tasks, choose housing materials and finishes matching aesthetic requirements or corrosive environment resistance, and configure mounting solutions accommodating unique installation challenges. Color temperature selection between 2700K warm white and 6500K cool daylight affects worker comfort and task visibility, with lower temperatures reducing eye strain during extended shifts while higher temperatures enhancing visual acuity for precision work requiring maximum contrast and detail resolution. Specialized optical systems beyond standard beam angles include asymmetric distributions optimizing light placement for specific geometries such as roadways, linear work zones, or building facades where symmetric patterns waste energy illuminating unnecessary areas while creating dark spots in critical locations. Construction Site Flood Lights can incorporate custom control interfaces, emergency override functions, integrated cameras for security monitoring, or environmental sensors measuring temperature, humidity, and air quality providing comprehensive site monitoring beyond basic illumination functions. OEM and ODM partnerships enable contractors and equipment rental companies to develop branded lighting solutions incorporating specific features, performance parameters, and aesthetic elements differentiating their offerings in competitive markets while ensuring fixtures meet exact operational requirements for specialized applications including mining, petrochemical, maritime construction, and other industries with unique lighting demands beyond general construction parameters.

Technical Specifications and Performance Validation

Quality Control Processes and Testing Protocols

Rigorous quality control represents the foundation of reliable Construction Site Flood Lights beginning with strict component selection verifying raw materials meet precise specifications for LED bins, driver components, housing materials, and optical elements before manufacturing commences. Advanced production line monitoring incorporates automated testing stations measuring electrical parameters, photometric characteristics, and mechanical assembly quality at multiple points throughout manufacturing processes, catching defects before they reach final assembly stages and ensuring consistent performance across production runs. Photometric testing using integrating spheres precisely measures total lumen output, beam patterns, color temperature, and color rendering index comparing results against specification targets and industry standards, with fixtures failing to meet minimum thresholds rejected before Packaging preventing substandard Construction Site Flood Lights from reaching customers. Extended aging tests subject completed fixtures to continuous operation under elevated temperatures simulating years of field service within compressed timeframes, identifying potential failure modes including LED degradation, driver component weaknesses, and thermal management inadequacies before products ship to construction sites where failures cause expensive downtime and safety hazards. Environmental testing exposes Construction Site Flood Lights to temperature cycling, humidity exposure, vibration, and impact scenarios verifying IP ratings, mechanical integrity, and operational stability under conditions exceeding normal field service expectations ensuring adequate safety margins for deployments in harsh environments where specifications represent minimum acceptable performance rather than typical operating conditions.

Certification Standards and International Compliance Documentation

| Certification | Scope | Importance for Construction Sites |

|---|---|---|

| UL Listed | Electrical Safety | Required for North American installations, ensures fixtures meet strict safety standards preventing fire and shock hazards |

| CE Marking | European Union Compliance | Mandatory for European markets, verifies conformity with health, safety, and environmental protection standards |

| DLC Premium | Energy Efficiency | Qualifies for utility rebates and incentives, validated performance claims ensure claimed efficiency meets independent testing |

| SAA Certification | Australian Standards | Required for Australian projects, demonstrates compliance with regional electrical safety requirements |

| ATEX/IECEx | Hazardous Location | Essential for petrochemical, mining, and oil & gas applications where explosive atmospheres require specialized lighting |

| RoHS Compliance | Environmental Protection | Restricts hazardous substances, facilitates disposal and meets environmental regulations in many jurisdictions |

| ISO 9001 | Quality Management | Demonstrates manufacturer commitment to consistent quality through documented management systems and continuous improvement |

| IP65/IP67 Rating | Environmental Protection | Verified dust and water ingress protection ensuring reliable operation in harsh weather and contaminated environments |

Comprehensive certification documentation provides construction managers, electrical contractors, and safety officers with confidence that Construction Site Flood Lights meet applicable standards and regulations, simplifying specification processes and reducing liability concerns for projects subject to code compliance reviews and safety inspections. The investment in obtaining multiple international certifications demonstrates manufacturer commitment to quality and facilitates global deployment of Construction Site Flood Lights across projects in diverse regions without requiring separate product lines or extensive retesting for each market. Independent third-party testing and certification provides objective verification of manufacturer claims regarding performance, safety, and reliability, protecting buyers from misleading specifications and ensuring Construction Site Flood Lights deliver expected capabilities under actual field conditions rather than optimized laboratory environments. Maintaining current certifications requires ongoing compliance as standards evolve, ensuring Construction Site Flood Lights incorporate latest safety features, efficiency improvements, and environmental protections rather than remaining stagnant with obsolete designs that may eventually fail to meet updated code requirements.

Packaging and Transportation for Global Project Deployment

Professional packaging protects Construction Site Flood Lights during international shipping across multiple transportation modes including express courier services, air freight, rail transport, and ocean shipping, with each method requiring appropriate protective measures preventing damage from vibration, impacts, and environmental exposure during transit. Individual fixtures receive multi-layer protection starting with plastic bags preventing moisture and dust contamination, followed by custom-cut foam bases providing secure cushioning against impacts and preventing movement within cartons during handling and transportation. Top foam layers incorporate dedicated compartments organizing accessories including mounting brackets, chains, screws, and technical documentation ensuring all components remain together and protected throughout the shipping process, eliminating lost parts and simplifying installation when Construction Site Flood Lights arrive at remote project sites. Sealed cartons reinforced with strong packing tape and plastic strapping provide structural integrity withstanding stacking loads and rough handling common in international freight operations, while optional wooden crates offer additional protection for bulk shipments or particularly valuable orders requiring maximum security during long-distance transport. Transportation timing and cost optimization considers project schedules with express services delivering within 3-7 days for urgent requirements up to 300kg, air freight providing 5-10 day transit for larger quantities exceeding 300kg, rail options spanning 18-22 days for substantial shipments over 500kg traveling established routes like China-Europe Railway Express, and economical sea freight requiring 15-50 days for non-urgent cargo exceeding 2 cubic meters offering lowest per-unit costs for budget-conscious projects.

| Transportation Time | Shipping Option Details | Recommend Weight |

| 3-7 days | International Express(DHL, FedEx, UPS, TNT, etc.) | 0.5KG-300KG(optimal for cost efficiency under our contarated express rates) |

| 5-10 days | By Air (Airport-to-port or Airport-to-door) | 300KG+(Significantly more economical than express shipping for heavy cargo) |

| 18-22 days | By Rail(China-Europe Railway Express) | 2CBM/500KG+(More economical than air freight for large shipment with flexible timelines) |

| 15-50 days | By Sea(FLC/LCL) | 2CBM/500KG+(Much more economical than rail,suit for non-urgent cargo, also the most cost-effective shipping method) |

Conclusion

Selecting top-rated Construction Site Flood Lights engineered for harsh environments ensures your projects benefit from reliable, efficient illumination that enhances safety, productivity, and operational economics throughout demanding construction timelines. Advanced LED technologies, robust construction, and intelligent features deliver superior performance compared to outdated lighting solutions while meeting stringent international standards and environmental requirements.

Ready to illuminate your construction site with industry-leading performance? As a trusted China Construction Site Flood Lights manufacturer, China Construction Site Flood Lights supplier, and China Construction Site Flood Lights factory, Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers competitive Construction Site Flood Lights for sale with transparent Construction Site Flood Lights price and comprehensive China Construction Site Flood Lights wholesale options. Contact our expert team at sam@razorlux.com for customized solutions, technical specifications, and project-specific recommendations. Bookmark this guide for future reference when evaluating lighting solutions for your demanding applications.

References

1. Illuminating Engineering Society. "Recommended Practice for Roadway Lighting." ANSI/IES RP-8-22. New York: Illuminating Engineering Society, 2022.

2. National Electrical Manufacturers Association. "High-Intensity Discharge Lamps for General Lighting: Performance Testing and Requirements." ANSI C78.43-2023. Rosslyn, VA: NEMA, 2023.

3. U.S. Department of Energy. "LED Lighting: Understanding Performance Testing and Specifications." DOE Solid-State Lighting Program Report. Washington, DC: Office of Energy Efficiency and Renewable Energy, 2024.

4. International Commission on Illumination. "CIE Guide on the Limitation of the Effects of Obtrusive Light from Outdoor Lighting Installations." CIE 150:2017 (2nd Edition). Vienna: CIE Central Bureau, 2017.

5. Occupational Safety and Health Administration. "Construction Industry Standards: Illumination Requirements." 29 CFR 1926.56. Washington, DC: U.S. Department of Labor, 2024.

VIEW MOREoutdoor riding arena lights

VIEW MOREoutdoor riding arena lights VIEW MOREvolleyball lighting

VIEW MOREvolleyball lighting VIEW MOREled football field lights

VIEW MOREled football field lights VIEW MORE1000 Watt Led Stadium Lights

VIEW MORE1000 Watt Led Stadium Lights VIEW MORE120W Warm White Led Floodlight

VIEW MORE120W Warm White Led Floodlight VIEW MOREOutdoor Lighting For Volleyball Court

VIEW MOREOutdoor Lighting For Volleyball Court VIEW MOREDLC Led Stadium Lights 120lm/W 6000K Football Stadium Floodlights Fixtures

VIEW MOREDLC Led Stadium Lights 120lm/W 6000K Football Stadium Floodlights Fixtures VIEW MOREIP65 Atex 5000K Flood Light Reflector 75 CRI Explosion Proof Street Light

VIEW MOREIP65 Atex 5000K Flood Light Reflector 75 CRI Explosion Proof Street Light

_1750326878398.png)